ENSO’S PROGRESS IN THE ECO-SMART BATT PROJECT

First and second annuity (2020-2021)

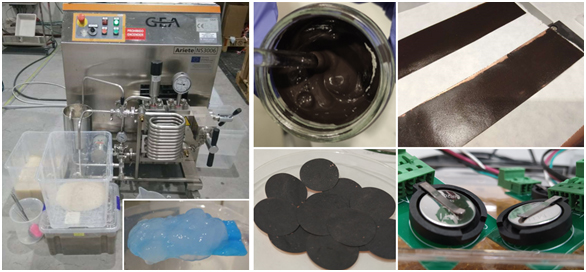

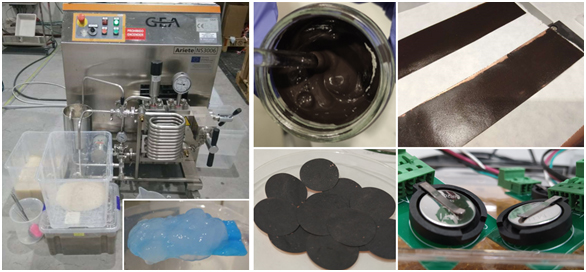

In the first months of the project, ENSO has carried out works related to the research and optimization of the process of obtaining nanoparticles; and in their application in anode materials, electrolytes and separators. These have been used, together with all those investigated within the framework of the project, for cell assembly and electrochemical testing.

In addition to the optimization of the processes to obtain nanoparticles, the evaluation of the drying stages, looking for a balance between energy consumption and nanoparticle quality, has been taken into account.

The preparation of anode material, electrolytes and separators based on this material has been started, testing their performance by assembling button cells and the corresponding electrochemical evaluation. Their performance has been evaluated against commercially available materials.

Third year (2022)

In the third year of the ECO-SMART BATT project, ENSO has continued with the work of studying and obtaining nanomaterials; preparation of electrochemical cell components, assembly of the cells and their electrochemical testing, going deeper into the preparation of the electrochemical components. Thus, progress has been made in obtaining composites based on nanosilicon and nanocellulose, seeking a high synergy between both types of nanoparticles. Likewise, we have made further progress in obtaining cellulose-based separators, confirming the feasibility of preparation from percentages of 10% of nanoparticles up to 100% of the same. Finally, progress has been made in the preparation of inks with the different materials of the consortium, reaching capacities between 310-330 mAh/g in reference cells. The micro/nanosilicon-based cells provided promising values.

Fourth annuity (2023)

In this fourth and final annuity project, we have pursued electrochemical cell components optimization. Using different types of nanocellulose obtained and optimised throughout project, ENSO has focused on the anodic inks optimisation with nanocellulose and silicon, both in their introduction as such and as carbon nanofibres; in electrolyte membranes based on aldehyde-modified nanocellulose and based on conventional LIPF6 electrolytes; and cellulose and nanocellulose separators, introducing nanocellulose in bulk or as a coating. In addition to physico-chemical characterisations, the materials have been evaluated in electrochemical tests. Through the studies, we have observed that nanocellulose has a great potential to act on the different cell components, and although the results are considered improvable, the electrochemical results shown by the cellulose separators have been outstanding, comparable to conventional polymer-based separators, thus achieving both technical and environmental competitiveness compared to traditional materials, with a commitment to materials of great global availability and of renewable origin.

Final results

Following its participation in the ECO-SMART BATT project, ENSO has broadened its expertise in obtaining cellulose nanofibres; starting from different types of biomass, applying different types of pre-treatment and treatment, and deepening the drying process to avoid particle agglomeration. All this, accompanied by an improvement, control and process optimisation, selecting those routes with a balance between fibre quality, energy consumption and cost. At the same time, this project has allowed ENSO to achieve greater involvement in the battery and automotive sector; developing itself anode materials, electrolytes and separators by introducing nanocellulose in them, achieving a potential improvement in the cells energy density, improving batteries sustainability by replacing materials from fossil sources with a renewable source, and seeking final product economic competitiveness by optimising the obtaining materials processes.